Dye Sublimation Printing

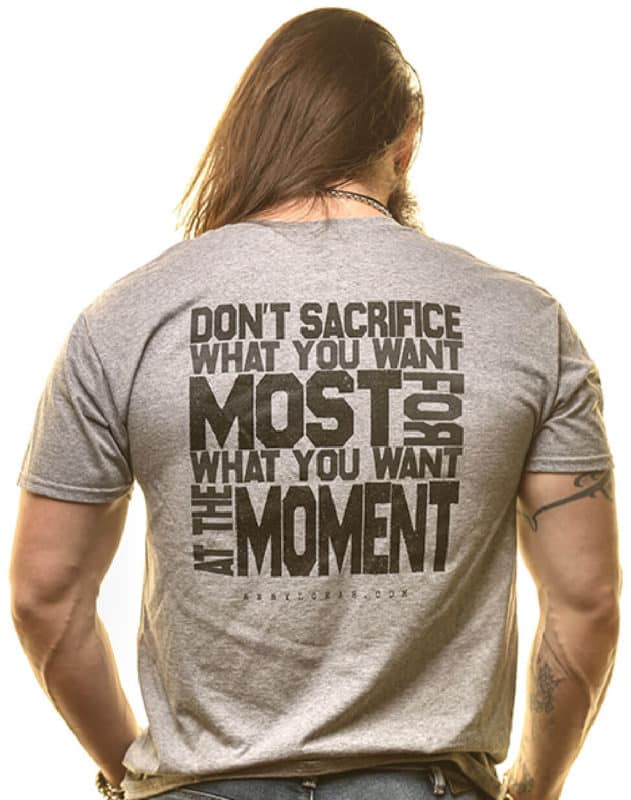

The Dye Sub process is changes the color of the shirt fibers, therefore, white and light grey are the most commonly used garment colors.

Dye Sublimation Printing, or Dye Sub, as it is often called, is a creative process that allows you to create designs with unlimited colors and detail. It is a 2-Step process that requires first printing out the design using a dye sublimation printer on a special dye sub transfer paper. The second step requires a heat press to dye the ink into the fibers of the shirt at 400 degrees.

Polyester is required to use the dye sub process. The most common polyester shirts are performance polyester, which has a shiny look. However, the demand for the creative dye sub process and cotton shirts has resulted in the major garment manufacturers developing a “cotton feel” polyester shirt.

The most common uses of the dye sub process is athletic jerseys. Since the fabric is dyed there is no excess ink on the garment giving a lighter more breathable jersey. In addition, the dye sub process allows more creativity with player names and numbers.